Fracture

Loss of containment is the prime failure mode to be designed against, with several potential failure locations and failure modes to assess.

Brittle fracture is a major concern for gas pipelines and needs to be avoided by ensuring the pipes are operated on the upper shelf. The Drop Weight Tear Test (DWTT) has been developed to replicate pipe behavior by a laboratory test suitable as production test. Several open questions (e.g. assessment of abnormal fracture) need to be answered to reflect current material and industry practice.

The size of allowable defects in girth welds has a major influence on the speed of pipelaying. EPRG Weld defect guidelines offer a safe but less conservative approach than solutions purely based on fracture mechanics.

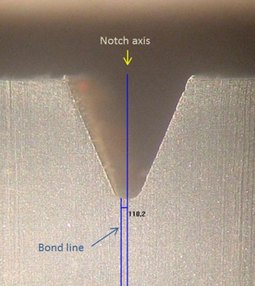

Suitable testing procedures in combination with adequate toughness requirements are the key to prevent failure in the welds. Bond line testing of High Frequency Welded (HFW) pipes is challenging due to the geometry of the bond line relative to the striker radius. The EPRG Procedure for CVN testing offers a solution that ensures meaningful test results.